Basic Info.

Model NO.

EEG-PCBA406

Condition

New

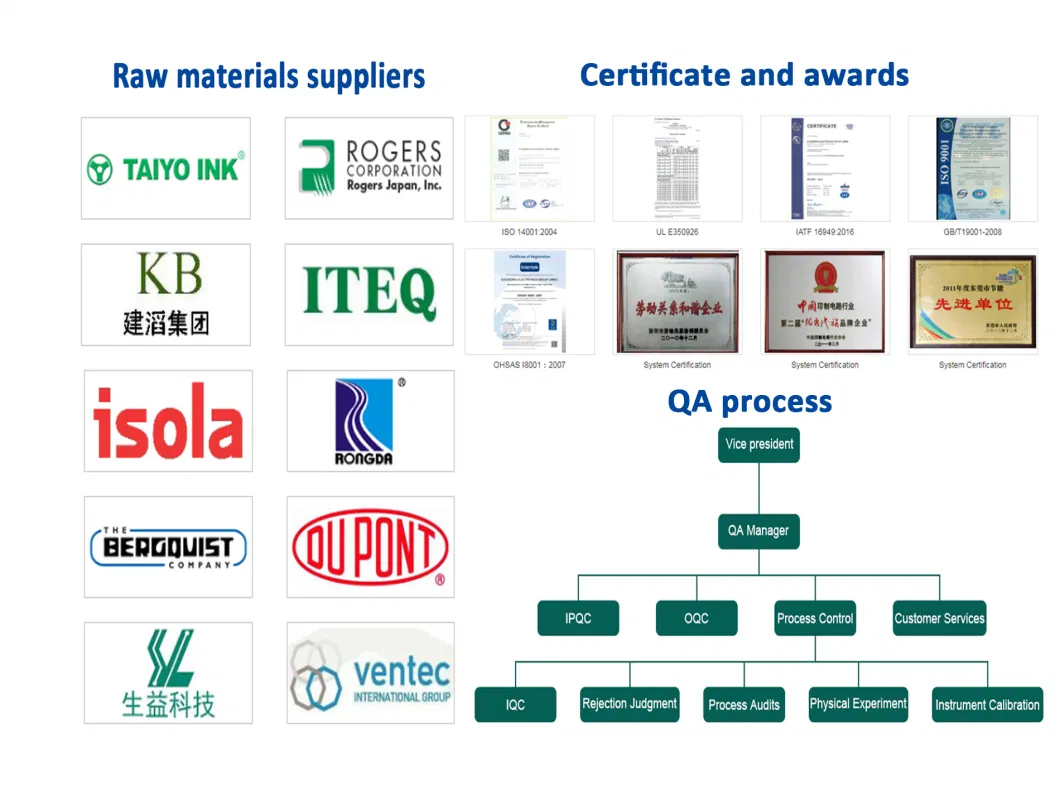

Certificate

ISO9001, ISO14001, IATF 16949, Ipc-a-610g, RoHS

PCB Material

Fr-4, Cem-1, Cem-3, Hight Tg, Fr4 Halogen Free

PCB Shape

Rectangular, Round, Slots, Cutouts, Complex

Solder Mask

Green/Black/White/Red/Blue/Yellow/Purple.etc

Board Thickness

0.2mm-8mm

Copper Thickness

18um-3500um(0.5- 100oz)

Service

PCB/Componentssourcing/Assembly/Test/Package

PCBA QA

X-ray, Aoi Test, in-Circuit Test (Ict)

Layer

1-36 Layers

Max. PCB Size

1900mm*600mm

Profiling Punching

Routing, V-Cut, Beveling

Surface Finishing

HASL/HASL Lead Free, Chemical Tin, Chemical Gold

PCB Type

Rigid PCB, HDI PCB, Flexible PCB, Rigid-Flexible

Test

X-ray, Aoi, in-Circuit Test (Ict), Functional Test

PCBA Packaging

ESD Packaging, Shockproof Packaging, Anti-Drop

Transport Package

ESD Bag+Bubble Wrapped +Carton

Specification

Customized PCBA

Trademark

EEG

Origin

Made in China

HS Code

8534009000

Production Capacity

30000/Month

Product Description

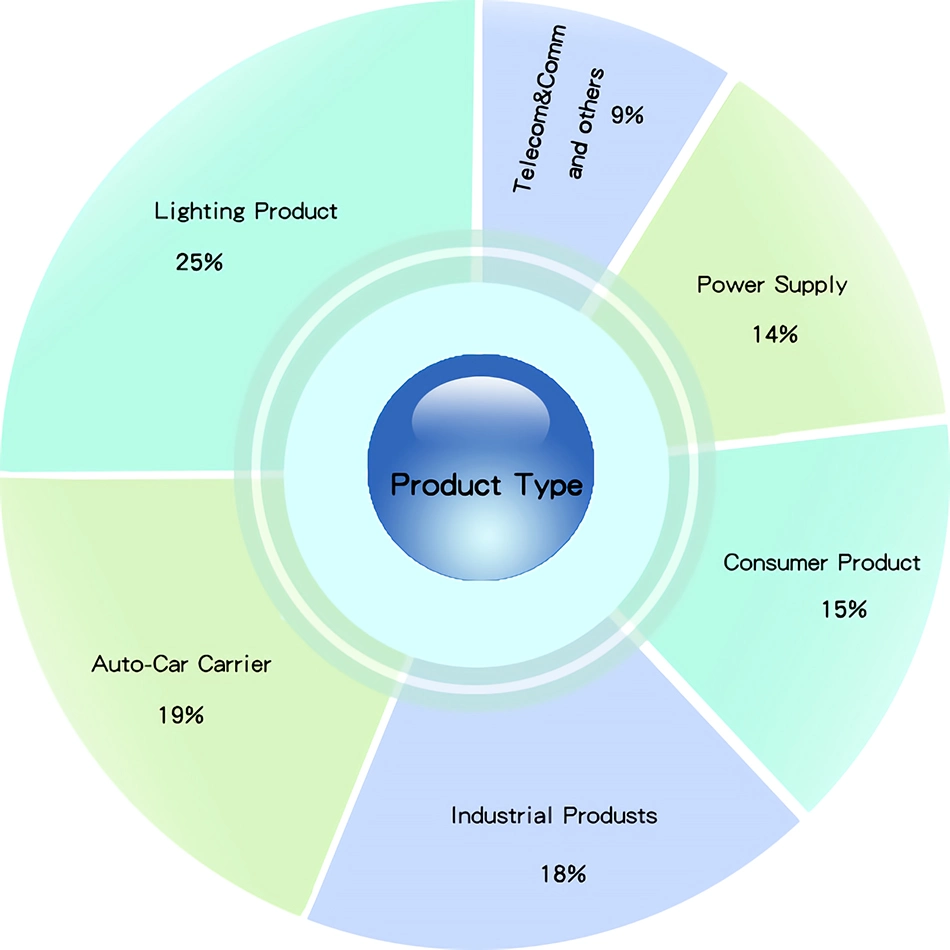

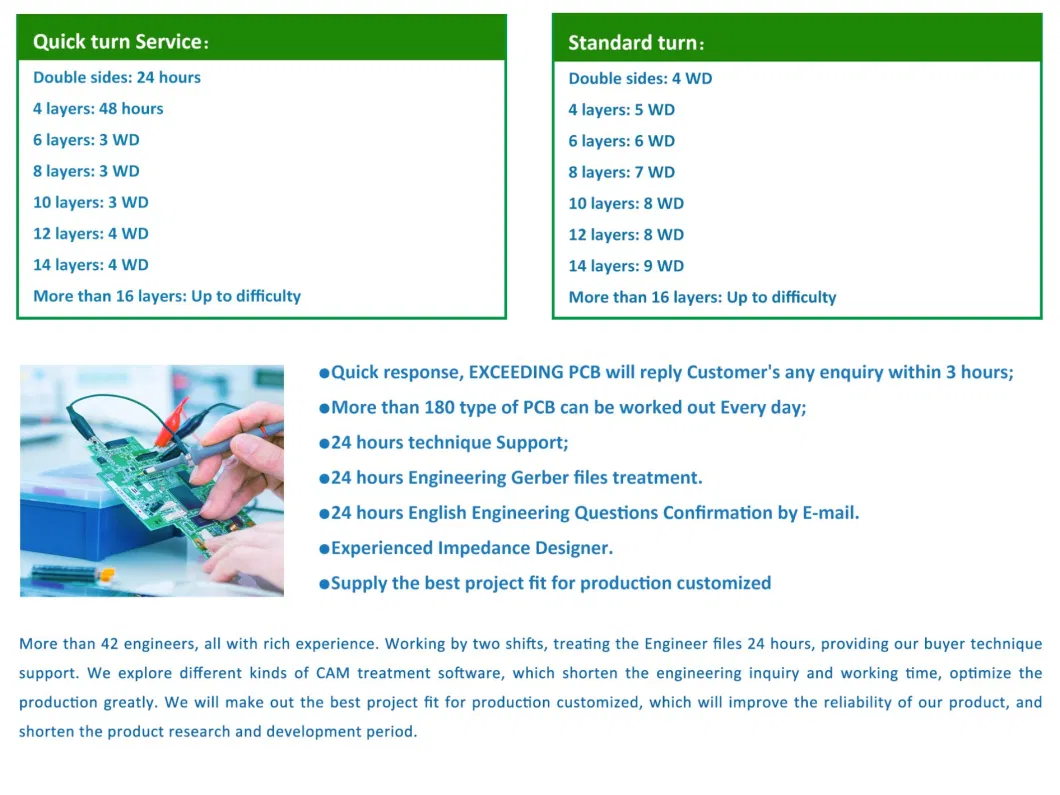

Founded in 2001,Exceeding Electronics Group Ltd,provides world-class customer support services. We are an industry lead in automotive, telecommunications, computer, industrial control, medical and power and energy PCB.

Buyers from international markets choose to source from us because of our high-production capacity and product development capabilities.

Our extensive list of products and features includes:

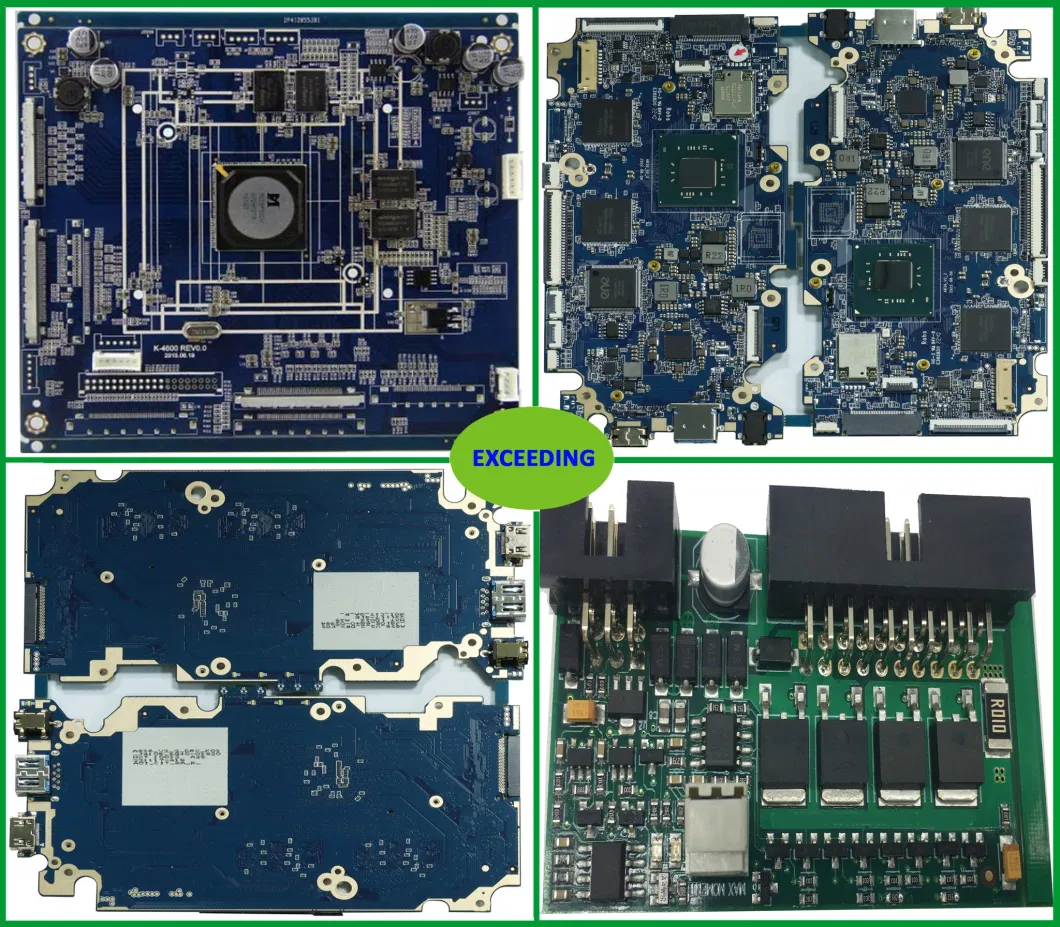

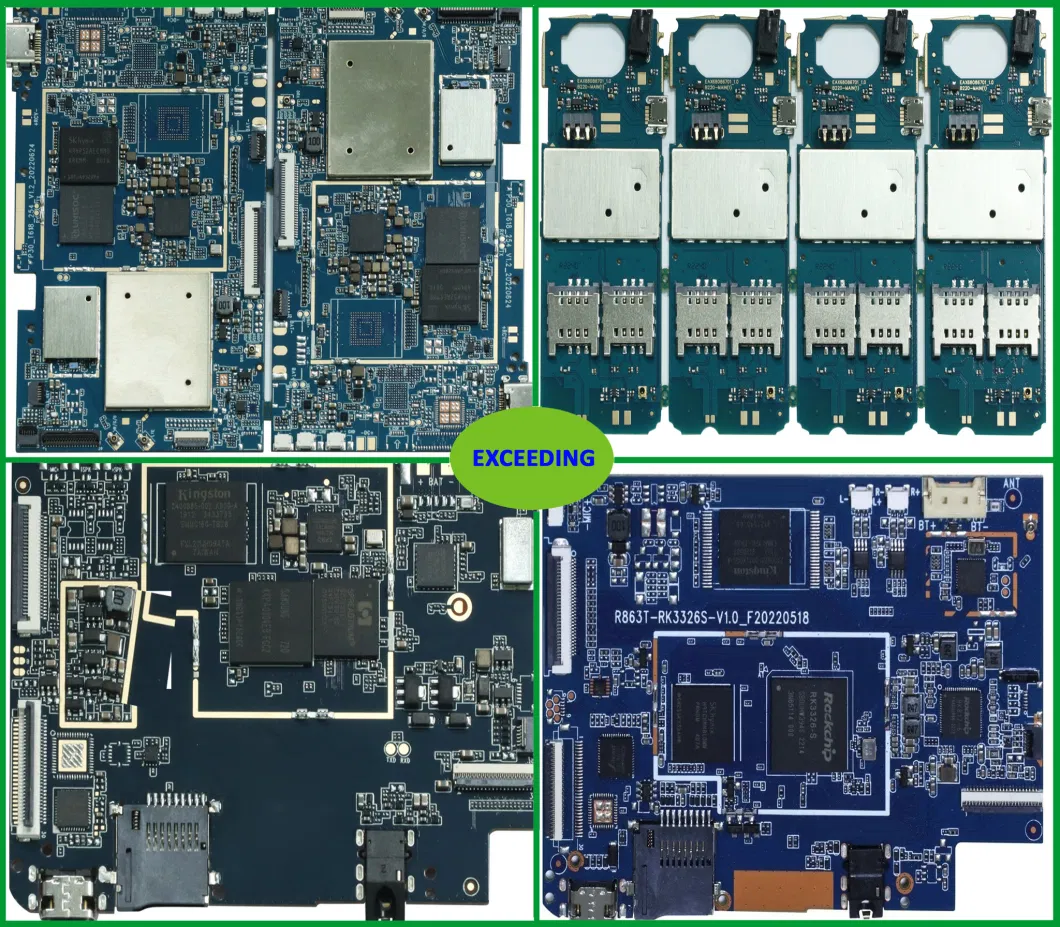

We are devoted to product quality and manufacturing efficiency,which is why we offer highly reliable solutions to customers worldwide. We manufacture PCBs to the strictest UL and IPC standards,utilizing state-of-the-art production equipment such as laser drills,LDIs,VCPs and more.Visit our online showroom or contact us today for more details.

Buyers from international markets choose to source from us because of our high-production capacity and product development capabilities.

Our extensive list of products and features includes:

| .1 to 36-layer rigid and 2-to 14-layer flex and rigid flex PCBs .Blind/buried vias with sequential lamination .HDI build up micro via technology with solid copper filled vias .Via in pad technology with conductive and non-conductive filled vias .Heavy-copper up to 12oz.Board thickness up to 6.5mm.Board size up to 1010X610mm. .Special materials and hybrid construction |

We are devoted to product quality and manufacturing efficiency,which is why we offer highly reliable solutions to customers worldwide. We manufacture PCBs to the strictest UL and IPC standards,utilizing state-of-the-art production equipment such as laser drills,LDIs,VCPs and more.Visit our online showroom or contact us today for more details.

Specification

| Term | Detailed Specification of PCBA Board Manufacturing |

| Layer | 1-36 layer |

| Material | FR-4, CEM-1, CEM-3, High TG, FR4 Halogen Free, FR-1, FR-2, Aluminum,Rogers,Taconic,Isola..etc |

| Board thickness | 0.4mm-4mm |

| Max.finished board side | 1900*600mm |

| Min.drilled hole size | 0.1mm |

| Min.line width | 2.95mil |

| Min.line spacing | 2.95mil |

| Surface finish/treatment | HASL/HASL lead free,Chemical tin/Gold,Immersion gold/Silver,OSP,Gold Plating,Gold finger. |

| Copper thickness | 0.5-100oz |

| Solder mask color | green/black/white/red/blue/yellow/purple |

| Inner packing | Vacuum packing,Plastic bag |

| Outer packing | Standard carton packing |

| Hole tolerance | PTH:±0.075,NTPH:±0.05 |

| Certificate | UL,ISO9001,ISO14001,ROHS,CQC,TS16949 |

| Profiling Punching | Routing,V-CUT, Beveling |

| Assembly Service | Providing OEM service to all sorts of printed circuit board assembly |

| Technical Requirement | Professional Surface-mounting and Through-hole soldering Technology |

| Various sizes like 1206,0805,0603 components SMT technology | |

| ICT(In Circuit Test),FCT(Functional Circuit Test) technology | |

| PCBA Assembly With CE,FCC,Rohs Approval | |

| Nitrogen gas reflow soldering technology for SMT | |

| High Standard SMT&Solder Assembly Line | |

| High density interconnected board placement technology capacity | |

| Quote&Production Requirement | Gerber File or PCBA File for Bare PCBA Board Fabrication |

| Bom(Bill of Material) for Assembly,PNP(Pick and Place file) and Components Position also needed in assembly | |

| To reduce the quote time, please provide us the full part number for each components, Quantity per board also the quantity for orders. | |

| Testing Guide & Function Testing method to ensure the quality to reach nearly 0% scrap rate | |

| PCB Assembly OEM Service | |

| Electronic Components Material Purchasing | |

| Bare PCB Fabrication | |

| Cable, Wire-harness Assembly, Sheet Metal, Electrical Cabinet Assembly Service | |

| PCB Assembly Service: SMT, BGA, DIP | |

| PCBA test: AOI, In-Circuit Test (ICT), Functional Test (FCT) | |

| Conformal Coating Service | |

| Prototyping and Mass Production | |

| PCBA ODM service |

| PCB Layout, PCBA Design According To Your Idea |

| PCBA Copy/Clone |

| Digital Circuit Design / Analog Circuit Design/ lRF Design /Embedded Software Design |

| Firmware and Microcode Programming Windows Application (GUI) Programming/Windows Device Driver (WDM) Programming |

| Embedded User Interface Design / lSystem Hardware Design |

PRODUCT SHOW

FACTORY AND EQUIPMENT

PACKAGE AND DELIVERY

What we need:

| * Gerber files of the bare PCB |

| * Bill of materials include: Manufacturer's part number, type of part, type of packaging,component locations listed by reference designators and quantity |

| * Dimensional specifications for non-standard components |

| * Assembly drawing, including any change notice |

| * Pick and Place file |

| * Final test procedures (if customer need us test) |

FAQ

Q:What files do you use in bare pcb fabrication?

A:Gerber RS-274X,274D,Eagle and AutoCAD's DXF,DWG,genesis2000...etc.

Q:What format of BOM List you prefer?

A:We prefer Excel format which include: Components Part No.,Manufacturer,Quantity,Value info...etc.

Q:How can i know the processing about my PCBA order?

A:Each Customer will have a sale to serve you. Our working hours: 9:00AM-18:30 PM from Monday to Friday,Saturday from 9AM to 12:30 PM. We will reply your email in 2hours in our working time. And you also can contact with our sales by phone if anything urgent.

Q:How long will we get the quotation after providing pcb gerber file,completed bom list,part datasheet and PNP file?

A: The quotation will be sent in less than 2 work days, for some special components which can't find here,you can suggest us the replacement PN or you can provide to us.

Q:If all PCBAs will be tested before delivery if we provide the function testing method?

A:Yes, we ensure that each piece of PCBA will be tested before shipment, we ensure the goods we sent out are with approved quality.

A:Gerber RS-274X,274D,Eagle and AutoCAD's DXF,DWG,genesis2000...etc.

Q:What format of BOM List you prefer?

A:We prefer Excel format which include: Components Part No.,Manufacturer,Quantity,Value info...etc.

Q:How can i know the processing about my PCBA order?

A:Each Customer will have a sale to serve you. Our working hours: 9:00AM-18:30 PM from Monday to Friday,Saturday from 9AM to 12:30 PM. We will reply your email in 2hours in our working time. And you also can contact with our sales by phone if anything urgent.

Q:How long will we get the quotation after providing pcb gerber file,completed bom list,part datasheet and PNP file?

A: The quotation will be sent in less than 2 work days, for some special components which can't find here,you can suggest us the replacement PN or you can provide to us.

Q:If all PCBAs will be tested before delivery if we provide the function testing method?

A:Yes, we ensure that each piece of PCBA will be tested before shipment, we ensure the goods we sent out are with approved quality.