Basic Info.

Model NO.

PCBA 90

Base Material

FR-4

Certification

RoHS, CCC, ISO

Customized

Customized

Condition

New

Service Items

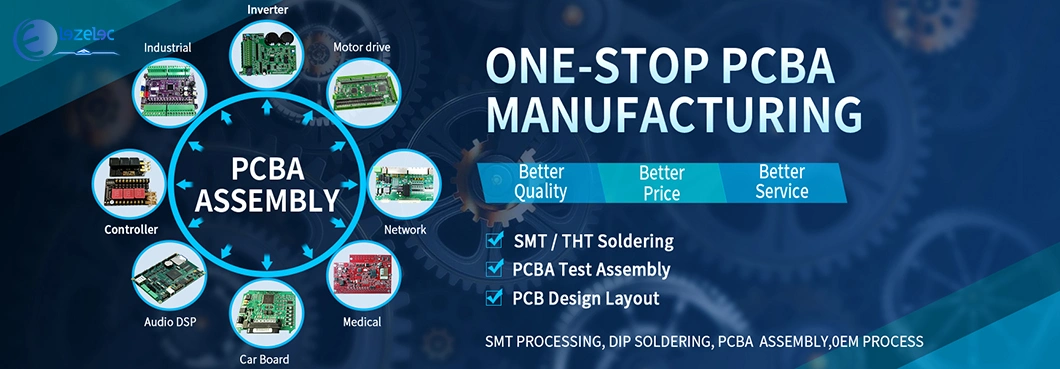

PCB Design, PCBA Assembly, PCBA Testing, One-Stop

Design Scope

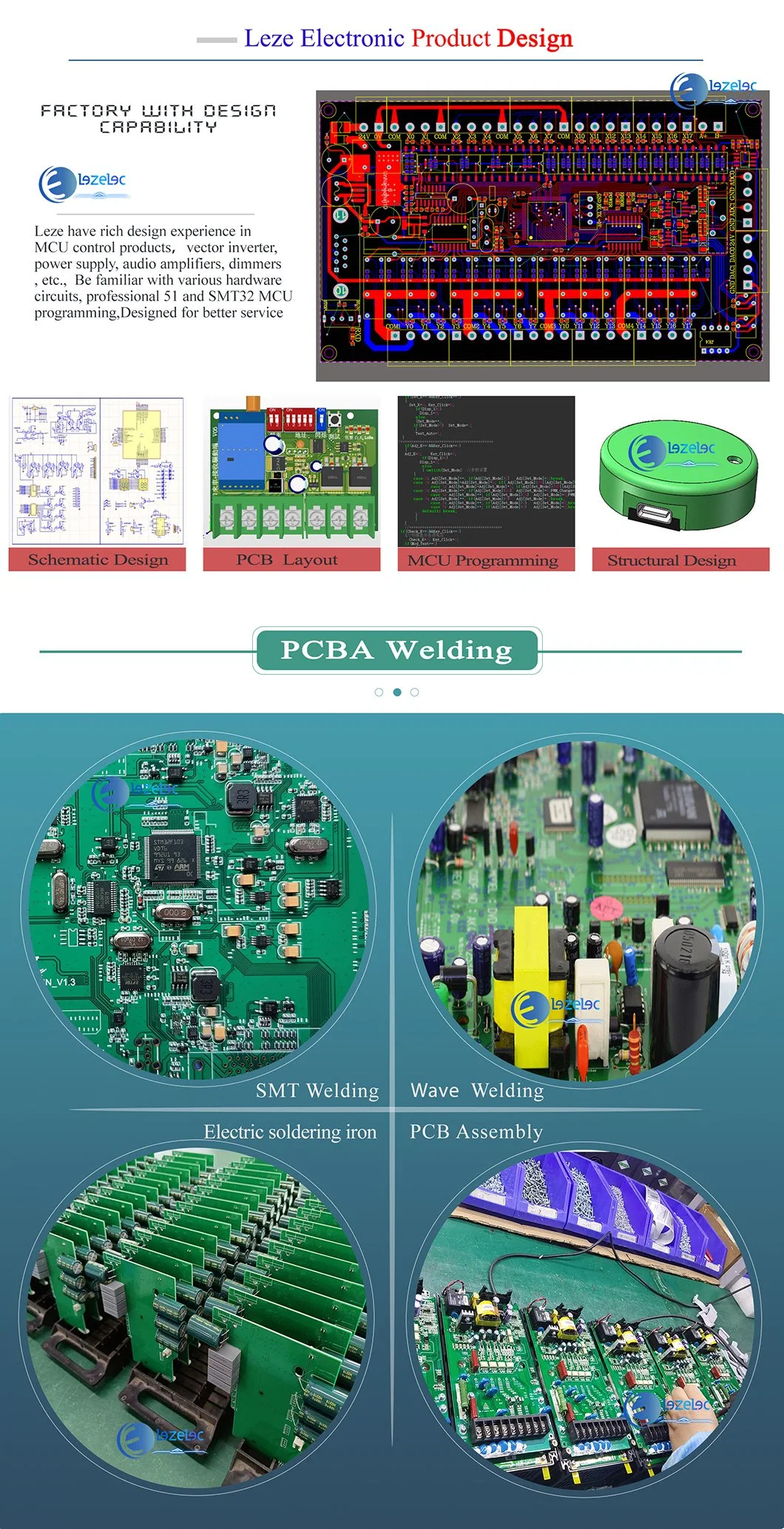

Schematic Design MCU Programming PCB Layout

Manufacturing Scope

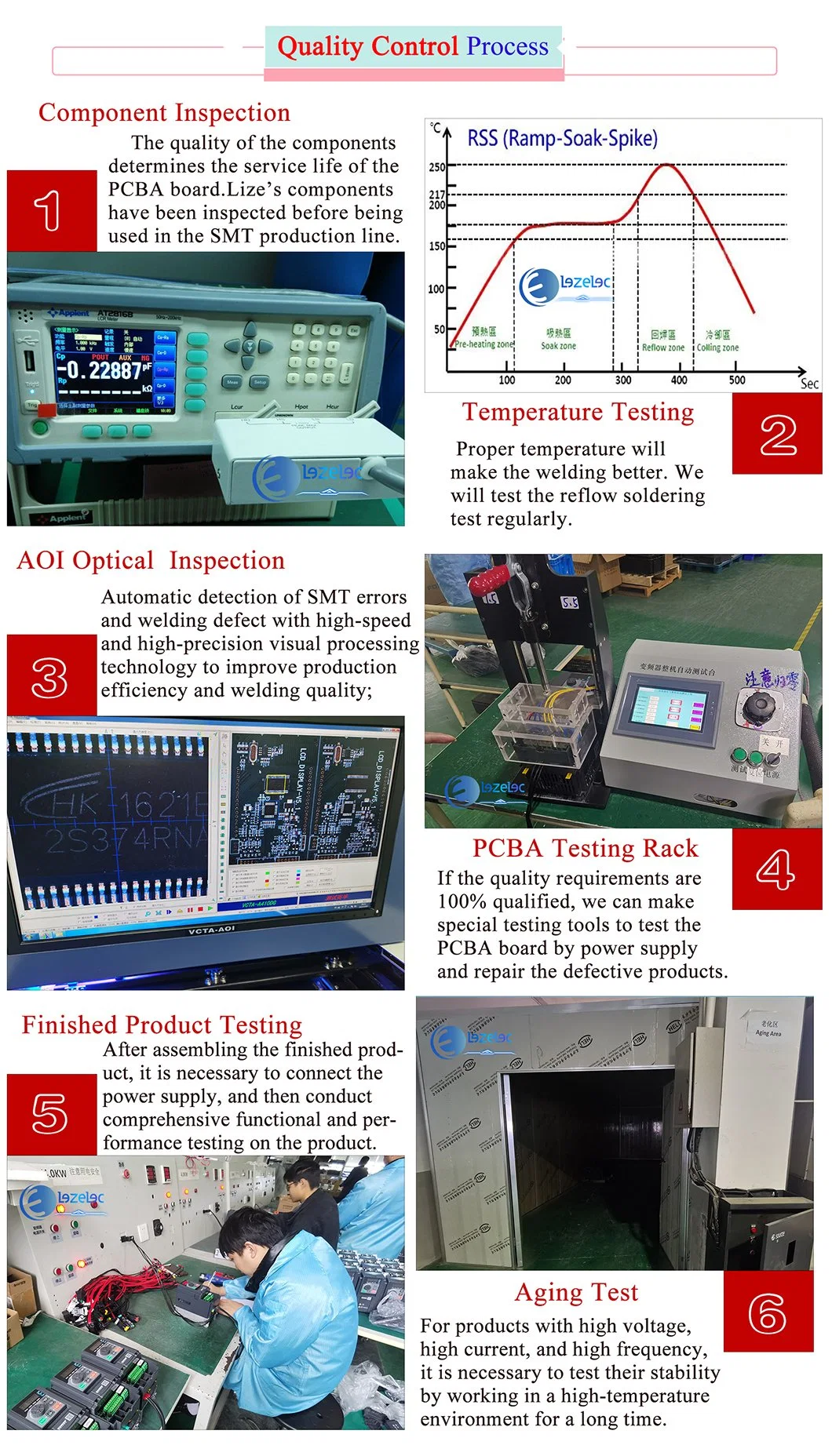

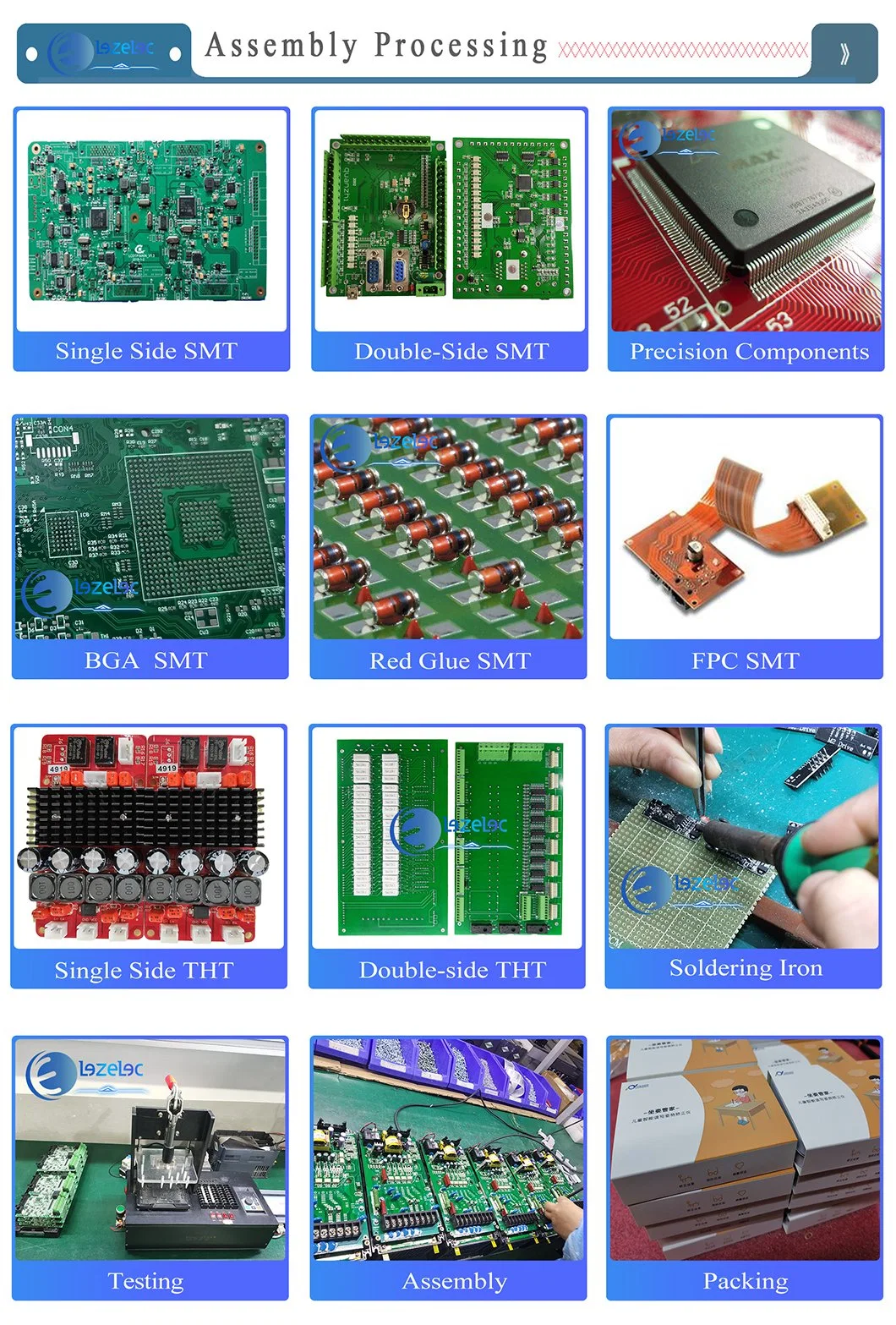

SMT Welding Tht Welding Aoi Testing Ict X-ray

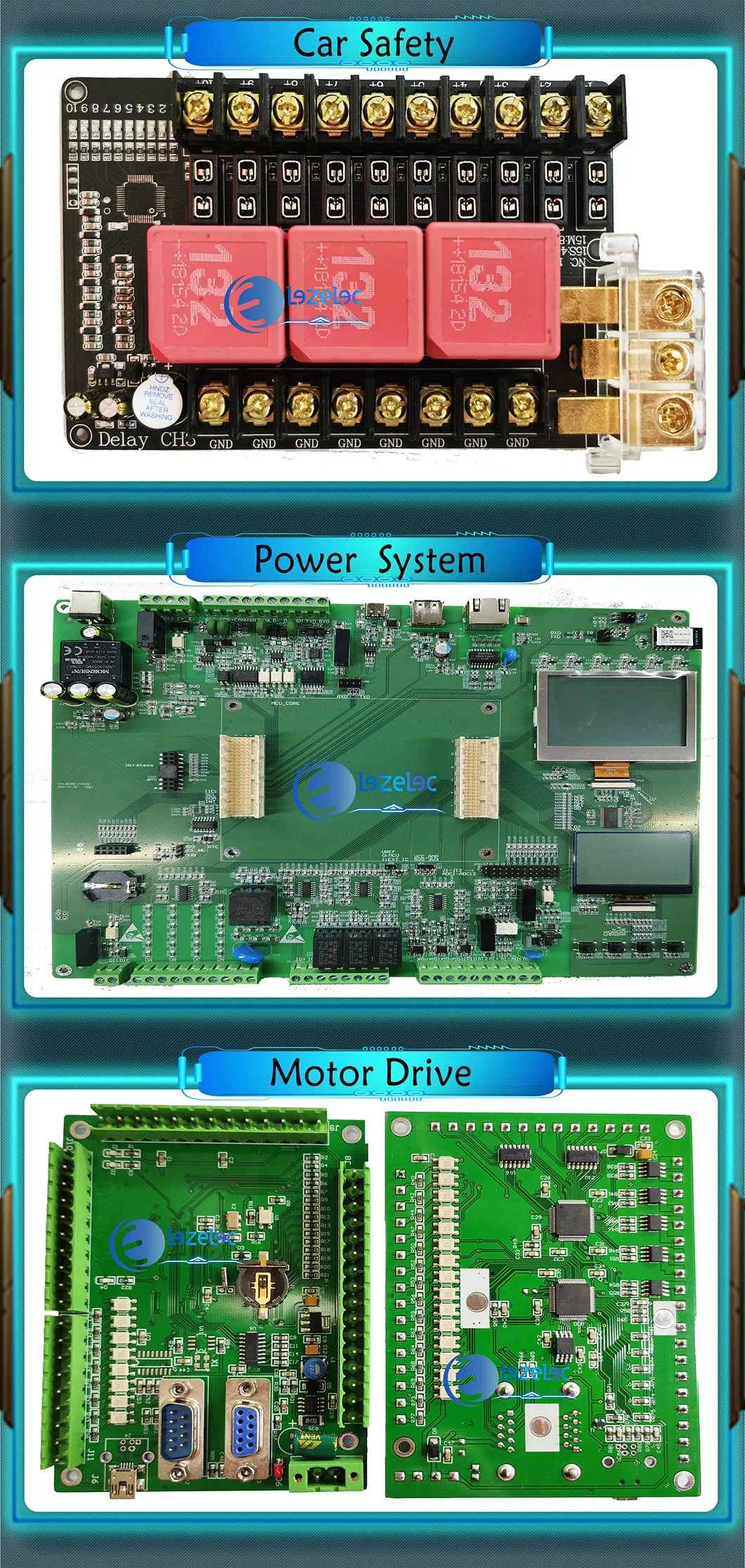

Product Application

Industrial Consumer Electronics Medical Equip etc

PCBA Packaging

ESD Bag/Vacuum Packaging+Bubble Bag, Customized

Other PCBA Service

Conformal Coating

Certificate

ISO9001/ISO14001/CE/RoHS

PCB Files

Aluminum, Gerber

PCB Layer

1-32 Layers

PCB Surface Finishing

HASL\OSP\Immersion Gold

PCB Thickness

0.2mm-7.0mm

PCB Solder Mask Color

Green; Red; Blue; Yellow; Black; White., etc

Application

Electronic Product

Transport Package

ESD Bag + Bubble Bag + Carton Box

Specification

230*340mm

Trademark

Leze & Vinsome & Hydroblus

Origin

China

HS Code

85340090

Production Capacity

300000PCS Each Month

Packaging & Delivery

Package Size

30.00cm * 20.00cm * 5.00cm

Package Gross Weight

0.250kg

Product Description

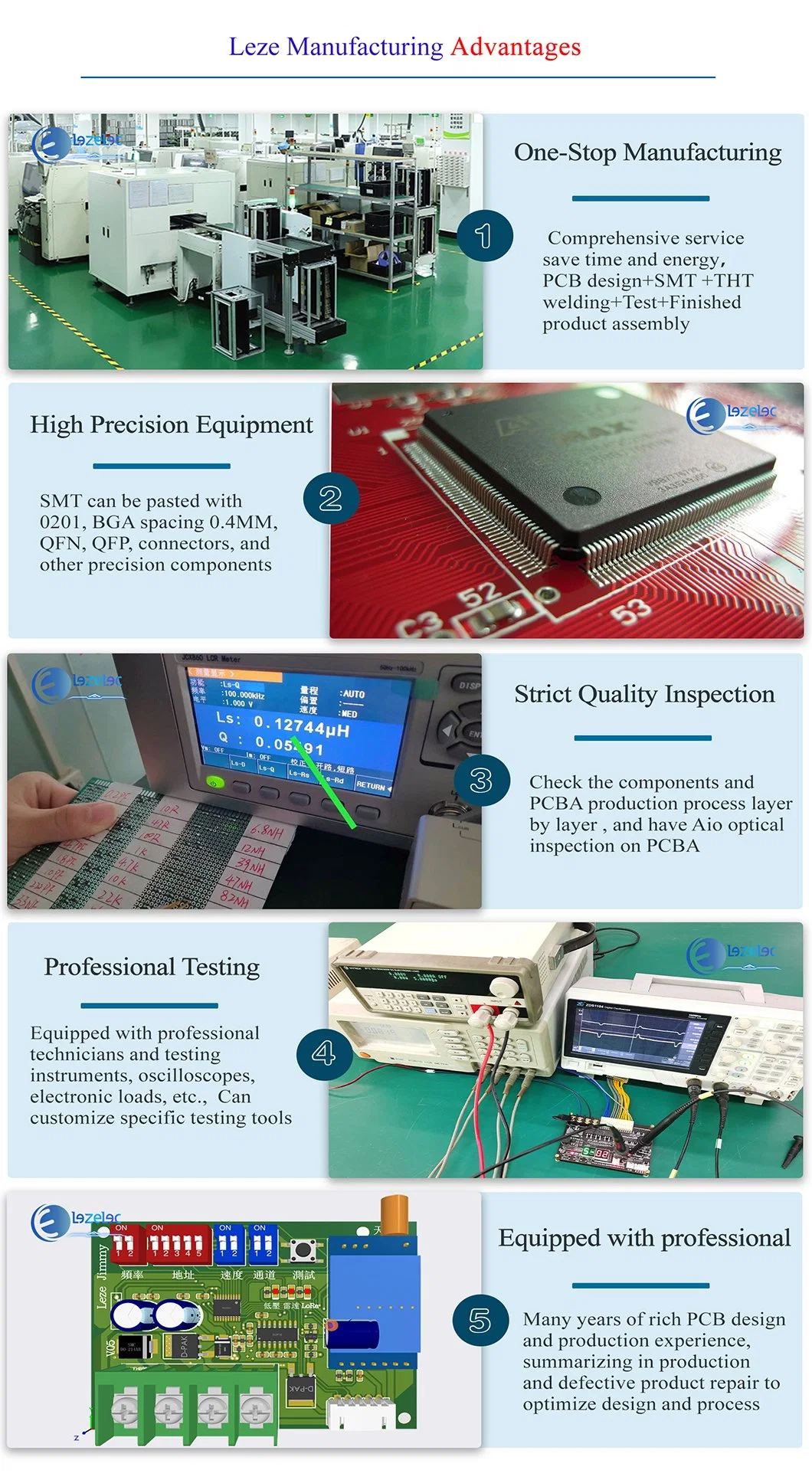

PCBA One-stop Design and Manufacturing

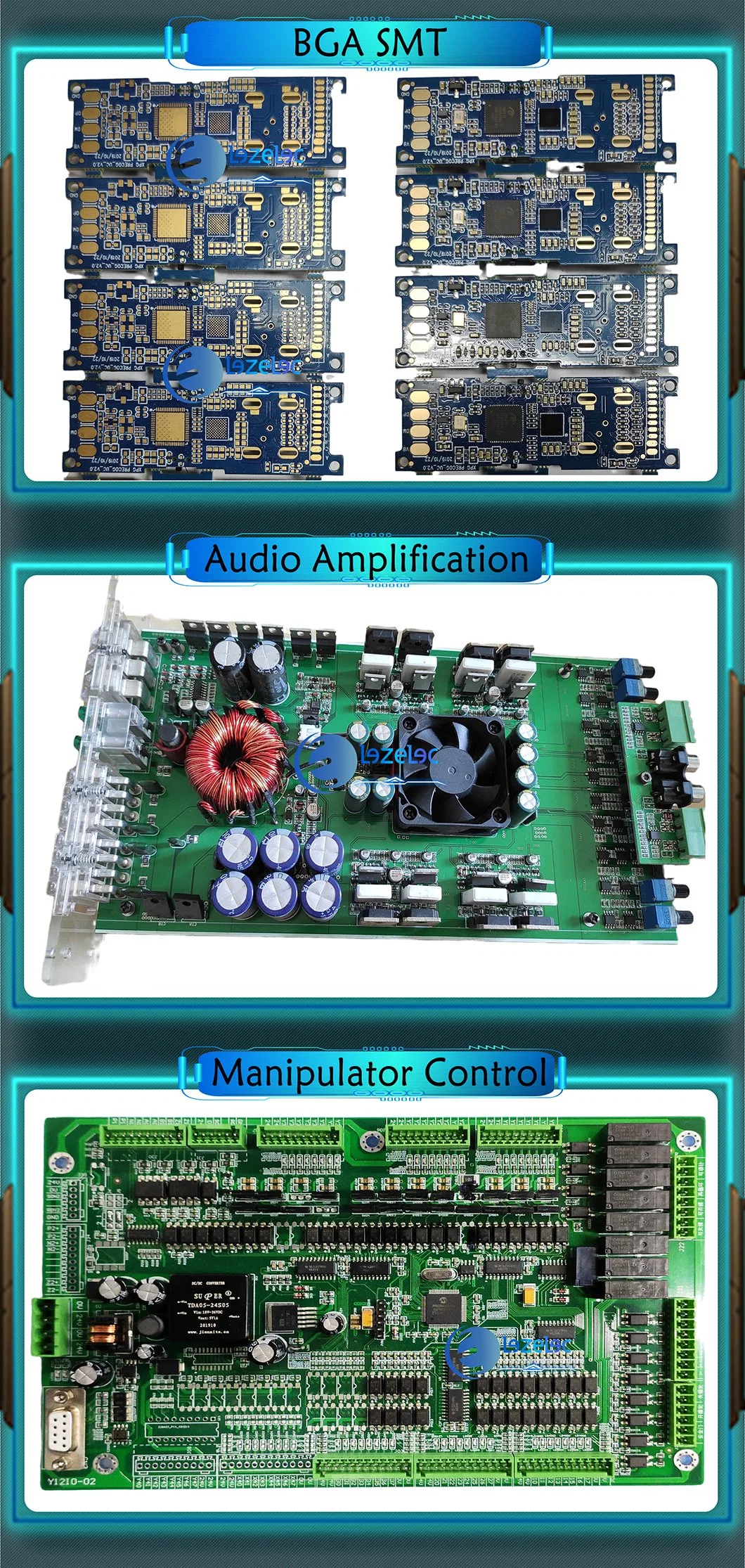

Leze Electronics Factory is located in Dongguan City. Our factory has been committed to providing customers with one-stop PCBA assembly and OEM services for PCB design, SMT welding, THT soldering, testing, and finished product assembly. At present, We has more than 5000 square meters of production plants, multiple SMT production lines, automatic printing machines, high-speed SMT machine, multi-functional SMT machine, reflow soldering , wave welding, AOI and other production and testing equipment, high-end SMT equipment and perfect management systems to meet the needs of different customers and products, and ensure your delivery and quality. In addition, some of our self-designed and produced products, such as VINSOM vector inverter, industrial control boards, Power inverters, etc., have been stable and reliable in use for many years, and with significant price advantages, we can also provide customers with OEM sales.

| Leze Design | Schematic design | Component selection and brand selection |

| Mcu programming | 51 Series MCU and SMT32 Programming | |

| PCB Layou | Conforming to the structure, considering electrical direction, current magnitude, and electromagnetic compatibility | |

| Structural design | AutoCAD ,UG,Creo,CATIA,Solidworks | |

| components | Selection and brand of components |

| PCB Board | PCB Layers | 1-28 layers, FR4, FPC, Aluminium |

| Thickness | 0.2mm ~ 7.0mm(8mil-276mil) | |

| Hole Tolerance | PTH:±0.076mm(+/-3mil), NTPH:±0.05mm(+/-2mil) | |

| Soldermask Color | Green, Red,Blue,Yellow,White, Black, etc | |

| Surface Finishing | HASL, Lead-Free HASL, Gold plating, OSP, etc. | |

| PCB Certificate | UL, ISO9001, ROHS, SG |

| PCBA Manufacturing | Purchase | High quality components determine the quality of the product |

| SMT Soldering | 0603,0805, SOP, TSSOP, QFP,QFN, BGA, etc Min:0201 | |

| THT Welding | Ai, Wave welding | |

| Testing | AOI, ICT test, FCT test , X-RAY | |

| Box Build | BOX build, box assembly |

FAQ :

1. About quotation and PCBA manufacturing process

1).PCB Design: Product functional description, electrical description, and structural description. The more detailed the better, let's have a clear understanding of what to do. 2).PCBA Assembly: Quantity,PCB files,Gerber files, BOM, Technic requirements...

Please contact us and send the production documents to our email. We will provide a quotation based on the production documents.If it is only processing with incoming materials, the quotation can usually be made in about a day. If you want to purchase components, we need to communicate with you via email to learn more about product information and then inquire about the prices of the materials. After determining the brand of the materials, we can usually make a quotation within 2-3 days.

2. How can we ensure our information should not let the third party see our design?

Protecting customers' privacy is our primary insurance, and we are willing to sign NDA with the customer. 3.Always 100% test before delivery?

Usually, the finished product with the assembled shell requires 100% testing. If it's just a PCBA board, many customers only need AOi inspection and do not need power on testing. We will follow the customer's requirements for this.

Usually, the finished product with the assembled shell requires 100% testing. If it's just a PCBA board, many customers only need AOi inspection and do not need power on testing. We will follow the customer's requirements for this.

4.Do you have any minimum order quantity(MOQ) requirements?

No, we do not have an MOQ requirement. We can support your projects starting from prototypes to medium productions.

No, we do not have an MOQ requirement. We can support your projects starting from prototypes to medium productions.

5.Shipping cost?

The shipping cost is determined by the destination, weight, and packaging size of the goods, and we generally do not include shipping cost. If you need us to quote you the shipping cost, please let us know.