- Overview

- Product Description

- Application

- Product Parameters

- Our Advantages

- After Sales Service

- FAQ

- Packaging & Shipping

Basic Info.

Packaging & Delivery

Product Description

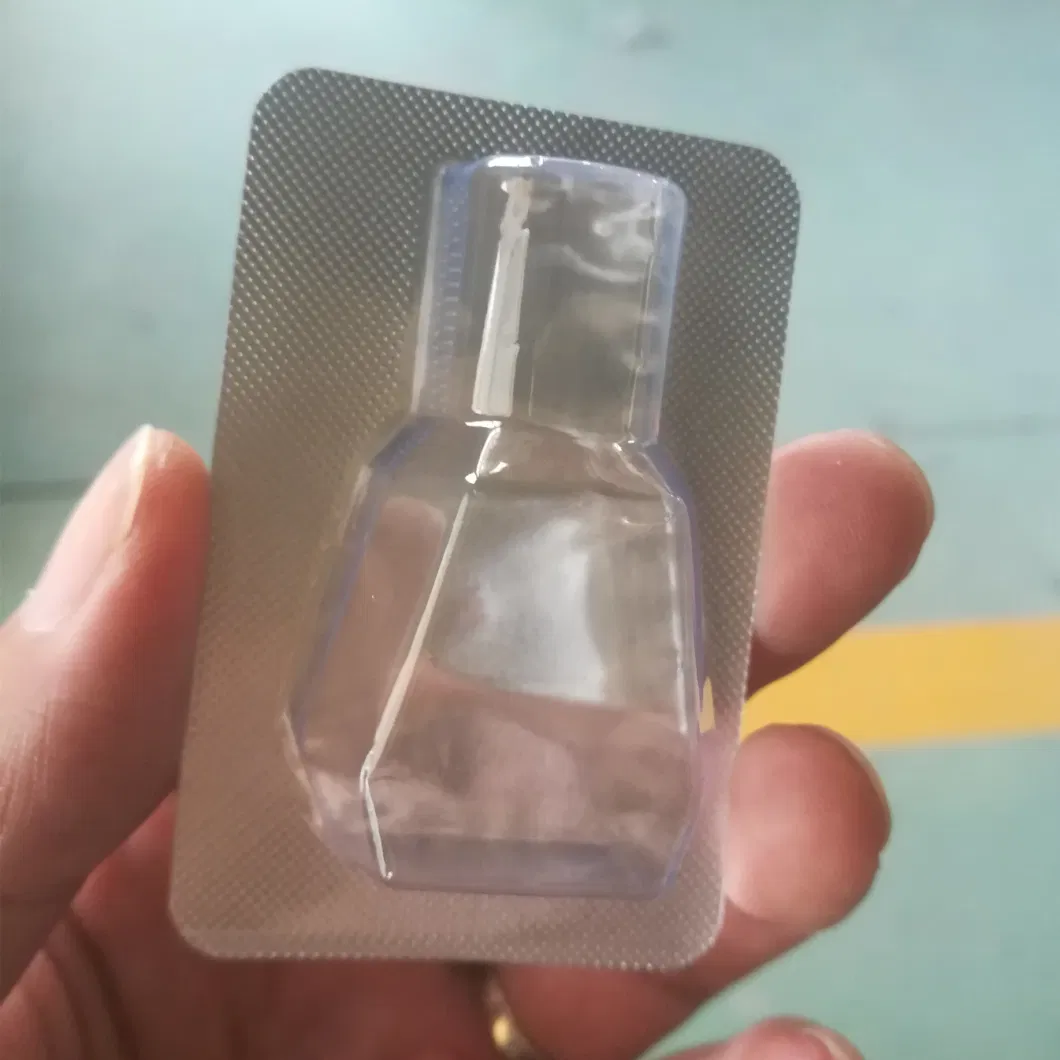

FAIR flat-plate Aluminum- aluminum, aluminum-plastic blister packaging machine which integrates many functions including feeding, heating, forming, PTP feeding, sealing of and PTP, batch number printing, indentation line making, etc. It is suitable for all capsules, tablets, sugar-coated tablets, honey pills, injections, ampoules, etc. CapsulCN The products have a long shelf life, good sealing performance, beautiful appearance, safety, and hygiene, conforming to the GMP production standards.

This blister packing machine is suitable for pharmaceutical, food, and health products industries, packing vegetarian tablets, sugar-coated tablets, and capsules, can also pack small pieces of food, hardware parts, and electronic components.

This packaging way(blister pack) can improve the product's quality, and enhance the product's added value.

| Model | FM-DDP-100 | FM-DDP-150F | FM-DDP-260 | FM-DDP-320 |

| Punch frequency | 10-33times/min | 10-33tims/min | 10-35times/min | 6-50times/min |

| Production capacity | 2400plates/hour | 2400plates/hour | 1200-4200plates/hour | 35000-23000pcs/hour |

| Max. Forming area & Depth | 105x70(standard depth <15mm) | 115x90(standard depth <15mm) | 145xll0(standard depth <15mm) | 240x70x26mm |

| Max. Depth 25mm | Max. depth 26mm | Max. depth 26mm | | |

| Standard Stroke range | 30-80mm | 35-90mm | 50-120mm | 40-160mm |

| Standard plate size | 80x57mm | 80x57mm | 80x57mm | 80x57mm |

| Air pressure | 0.4-0.6Mpa | 0.4-0.6Mpa | 0.4-0.6Mpa | 0.4-0.6Mpa |

| Compressed air required | Air compressor>0.3m3/min | Air compressor>0.3m3/min | Air compressor>0.3m3/min | Air compressor>0.3m3/min |

| Total power supply | 220V 50Hz 2.4Kw | 380V 50Hz 6.5Kw | 380V 50Hz 6.5Kw | 380V220v 50Hz 6.5Kw |

| Main motor | 0.75Kw | 1.5Kw | 1.5KW | 1.5KW |

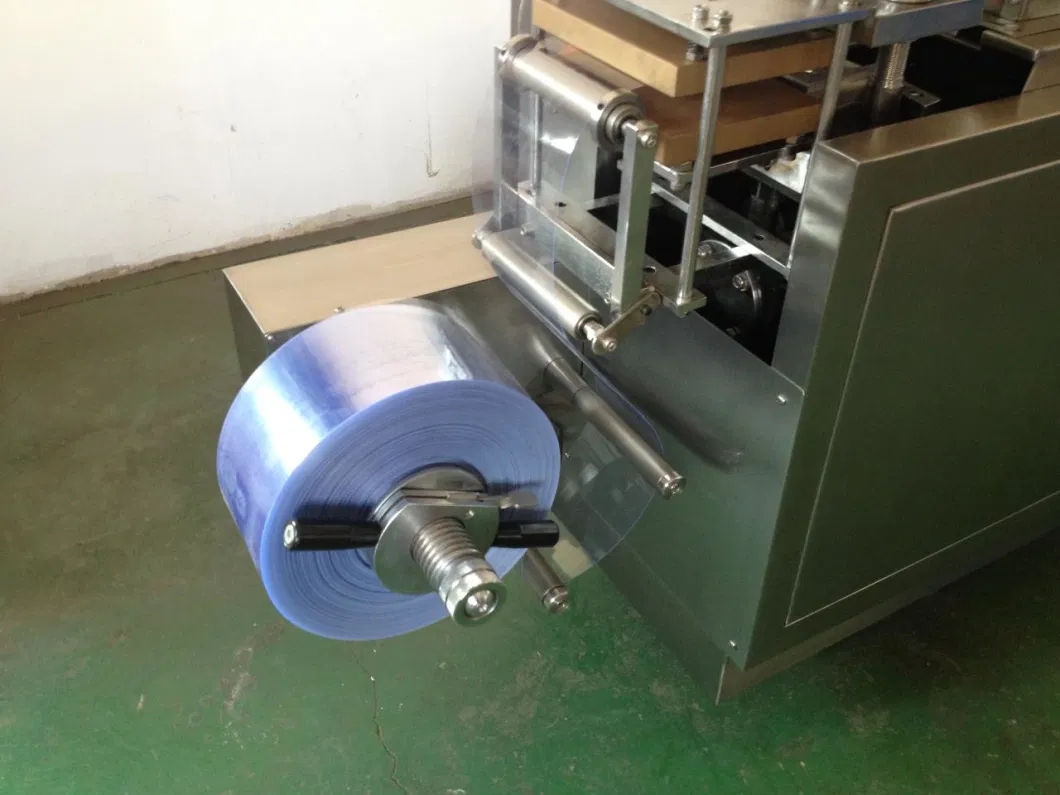

| PVC hard Film | 0.15-0.5xll0mm | 0.15-0.5X HOmm | 0.15-0.5x 160mm | 0.15-0.5x 160mm |

| PTP Aluminum film | 0.02-0.035 x HOmm | 0.02-0.035 x HOmm | 0.02-0.035 x 160mm | 0.02-0.035 x 250mm |

| Mold cooling | Tap water or Recycling water | Tap water or recycling water | Tap water or recycling water | Tap water or recycling water |

| Overall Dimension(LxWxH) | 1450x590x 1100mm | 2315×635×1405mm | 2715 x 685 x 1405mm | 3000x730x1600mm |

| Weight | 465kg | 820kg | 1150KG | 1400kg |

| Noise | <75dBA | <75dBA | <75dBA | <75dBA |

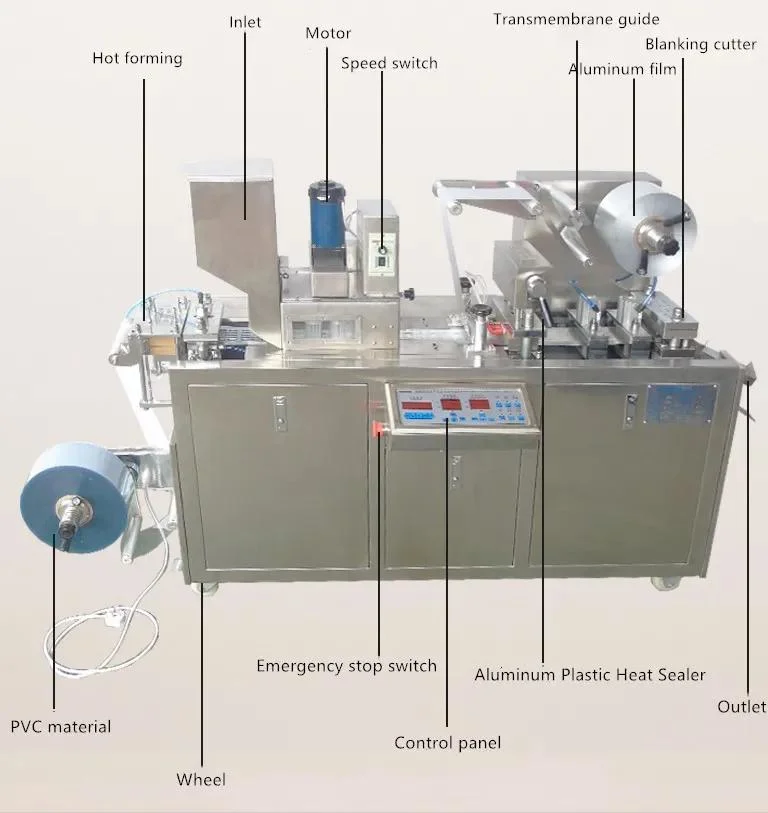

Work process:

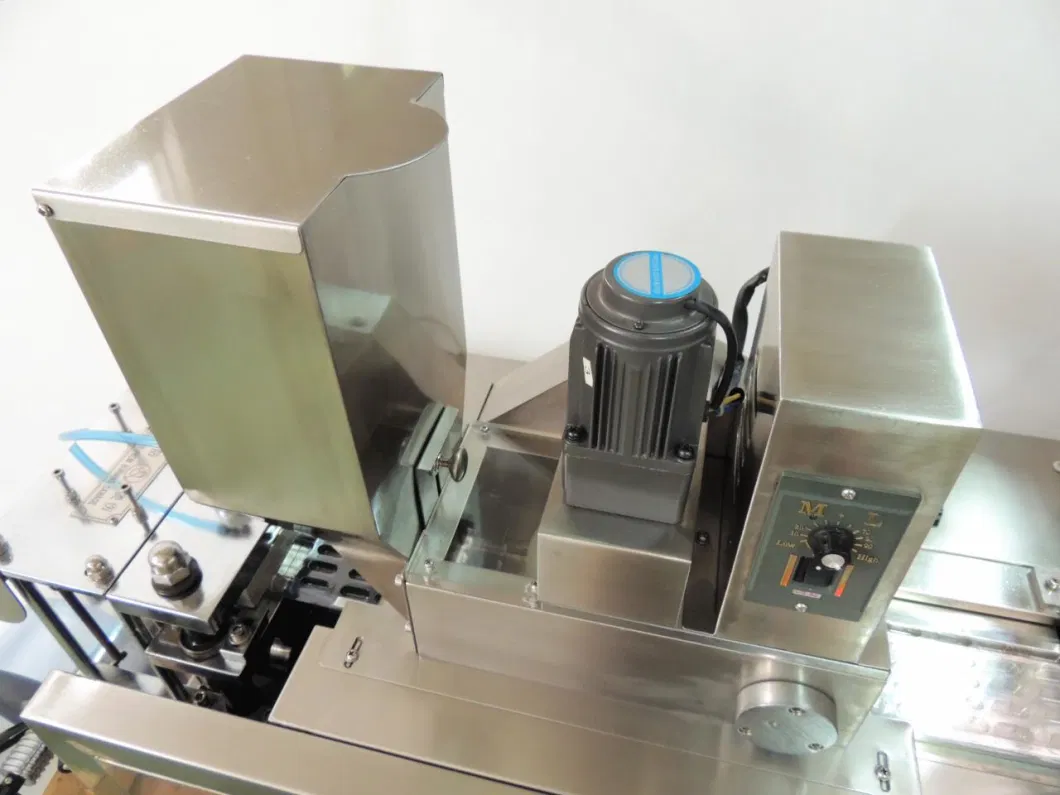

1. Forming (up and down heating)

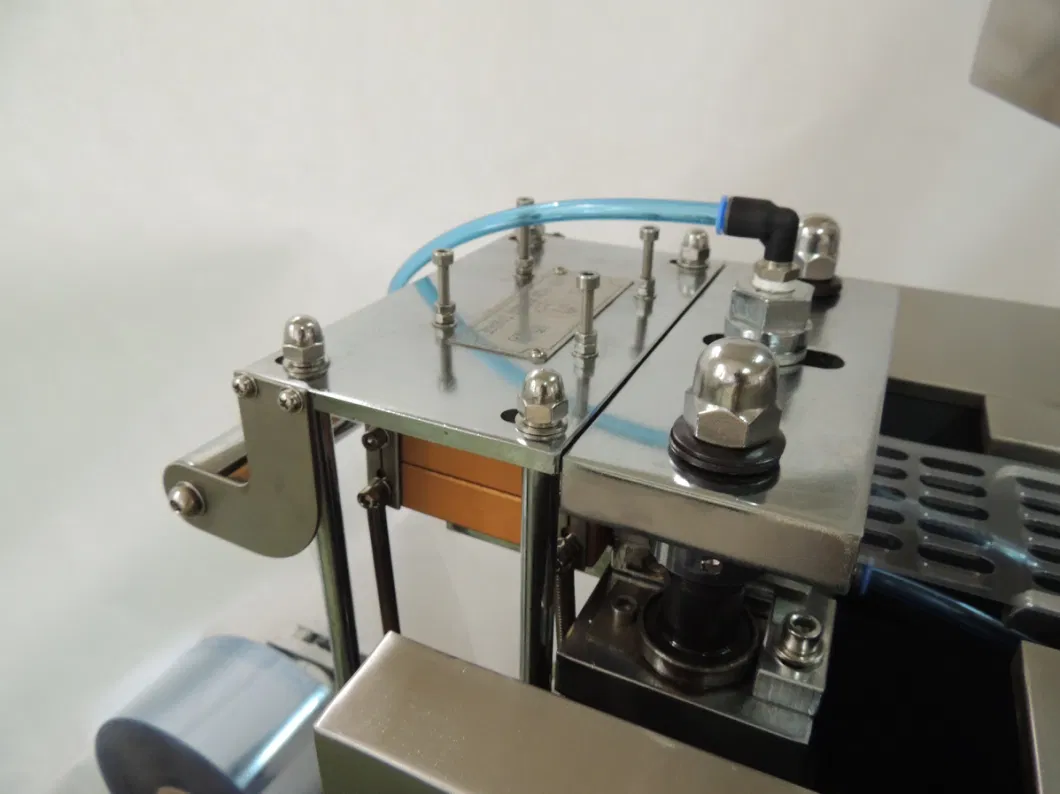

2. Heat sealing (upper heating)

3. Code

4. Indentation (can be heated in a small amount)

5. Cutter

6. Forming and outputting finished products

1. Faster Speed-Double heater plate and roller type sealing.

2. Easier Operation-Adopts top brand PLC controller displayed in Chinese and English, speed control, the length of blister traction adjustable

3. Thermal temperature control and test, overloading protection, PVC and PTP packing material position test, feeder, material position test, failure automatic debug and alarm, automatic protection and stop running.

4. Ensuring accurate registration -Adopts auto photoelectric register device for patterns and words of Al foil driven by step motor, perfect performance.

5. Discharging finished products in the right order -an automatic collection of bad products, and auto rewinding of strap material to ensure easy collection.

6. Auto closing and opening of forming plate helps delay the running time after dropping down the heat plate and also makes packing material efficiently used.

7. High Feeding efficiency, reliability, and suitable for many kinds type arrange and irregular feeding,(according to actual product design fit feeder)

8. Auto alarm and stop of the machine when PVC finds it to be lacking or ruptured provides much convenience to the operator for timely PVC replacement or joint PVC.

9. "GMP" requirements -All parts contact with material including the hopper adopt high-level stainless steel.

Pre-sale service

1. Support product customization, any requirements you need can be customized according to your requirements.

2. Sample test on our packing line.

3. Provide business consulting and technical support, as well as a free professional packaging solution

4. Make a machine layout for customers based on customers' factories.

After-sales service

1. Providing professional installation instructions and video of troubleshooting.

2. Providing machine control software updates and operation teaching in our factory.

3. Two years free maintenance for touch screen, inverter, PLC, temperature controller, and photoelectric sensor with freight prepaid.

4. Engineers are available to service the machinery overseas, and buyers pay 180 US dollars daily service fees and travel expenses.

5. Pick-up services at Nanjing Lukou airport, providing packaging solutions and testing material on machines, full refund if unsatisfied with the machine.

With rich industry experience and strict Product Quality Control systems, we provide:

1). Stable and reliable product at a reasonable price

2). Good customer service: Fast response to any inquiry or question

3). On-time delivery.

2: Do you have English Manual for each piece of machinery?

Yes. The instruction manual, the test report, and other Data Sheets related shall be provided by us.

3: Can you customize the machine for me?

Yes, we can customize it according to the customer's requirements.